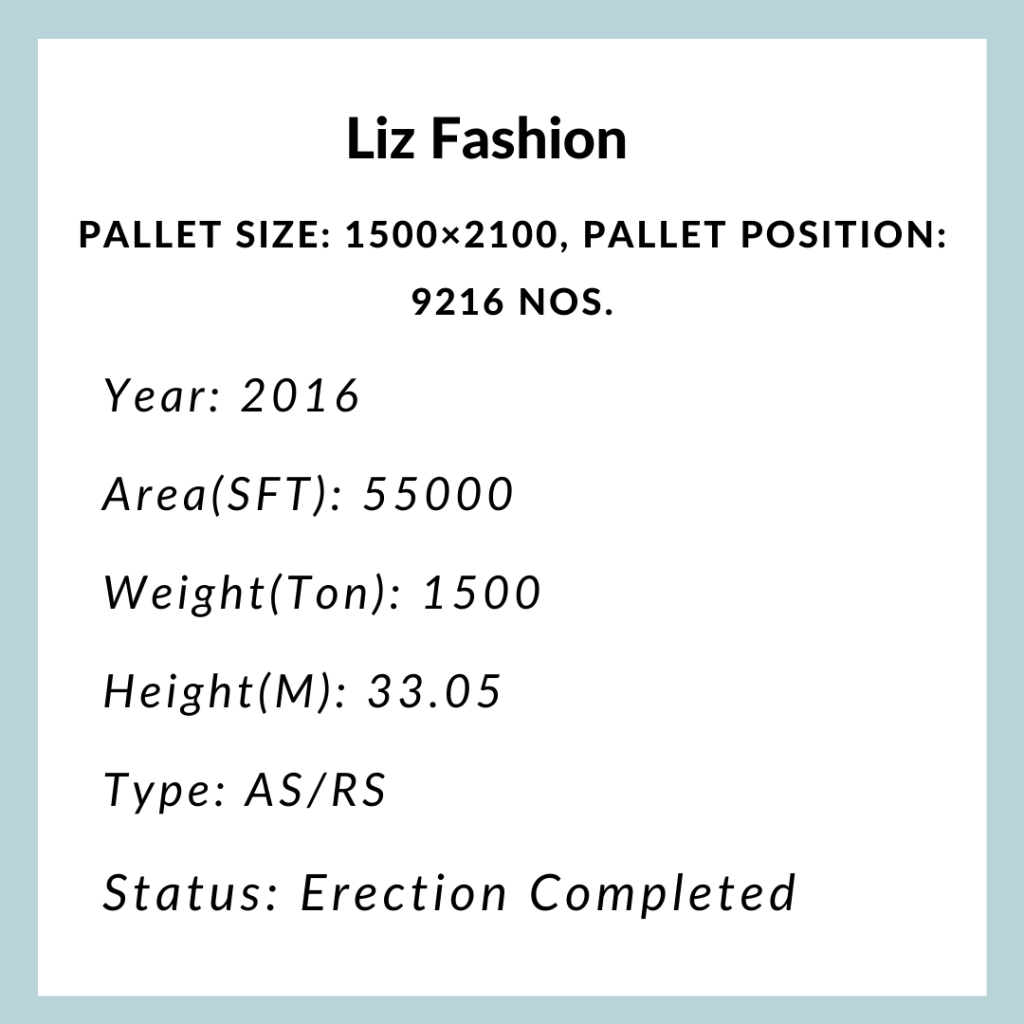

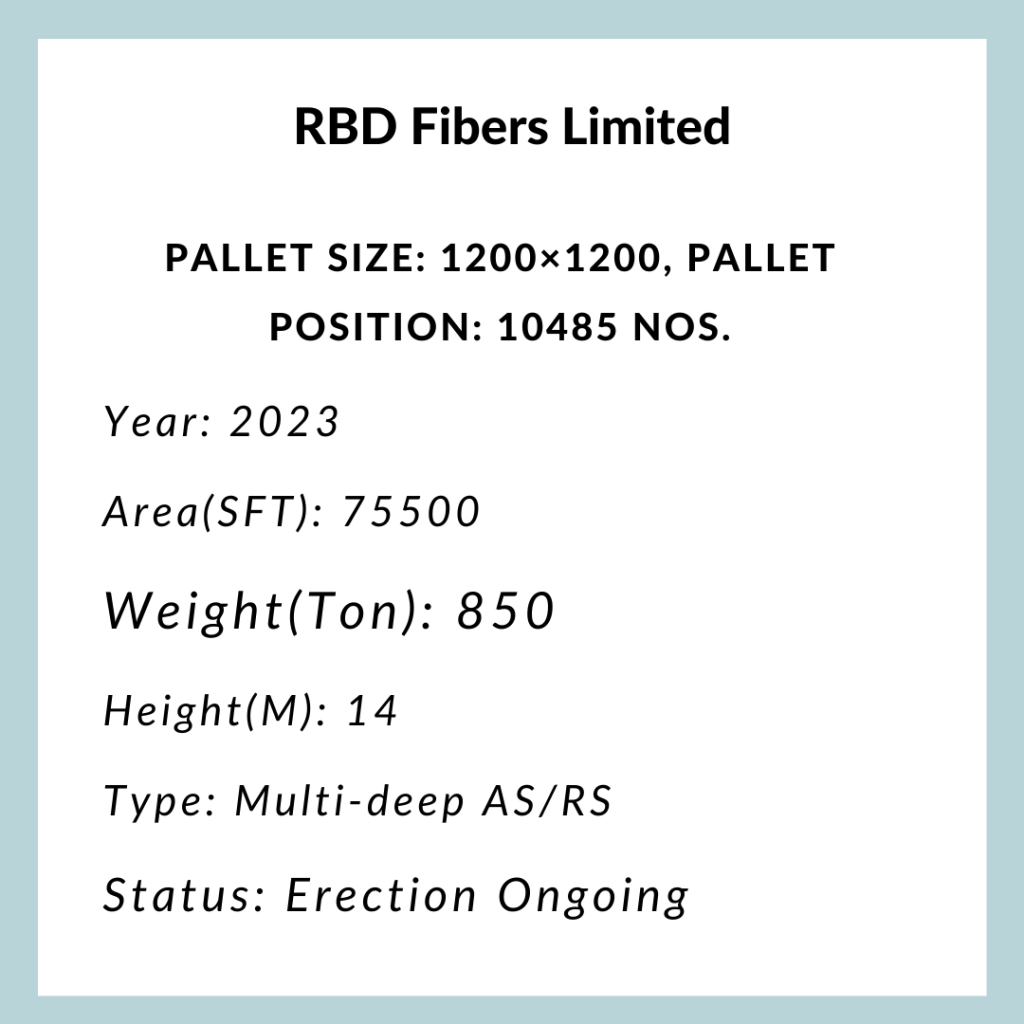

ASRS Racking System

(Automated Storage and Retrieval System) racking system is a specially designed to buffer, store, and retrieve products and inventory on demand by warehouse automation technology. It is most commonly used in manufacturing, distribution, retail, wholesale, and institutions. This is a fully computer-controlled operation. You can control each and every pallet and different type of goods at any time with one click.

There are many types of ASRS presently used all over the world and which is suitable for you depend on which product you want to keep in the warehouse. It consists of shuttles, cranes, carousels, vertical lift modules (VLMs), micro-loads, mini-loads, unit-loads, or other systems.

The automated Storage and Retrieval System racking system is integrated with a few software such as warehouse management software (WMS), warehouse control software (WCS), ERP, and warehouse execution software (WCS).

Each Pallet can support 500-1200 kg/Pallet which depends on the customer goods details. The customized pallet can also be used in this system.

ADVANTAGES

Possibility of storing medium to heavy loads.

Proper space utilization.

Greater capacity: deep store pallets in up to 300 ft. lanes and height up to 120 ft.

Increased inventory storage density and customer service

Increase the study of people’s efficiency in their working environment.

less Accidental.

Increased productivity, throughput (speed), and Efficiency.

Reduced labor and product damage costs.

Fewer labor constraints