Pallet Racking System Master Racks Limited

Are You Looking For A Pallet Racking System To Maximize The Current Warehouse

Space And Reduce The Suffocation In Your High-Density Storage Areas? Let

Explore…

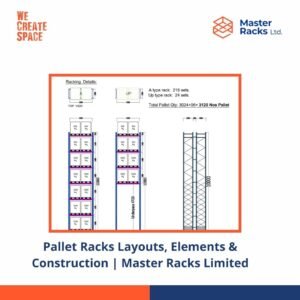

Warehouse Pallet Rack Layouts, Elements & Construction and how they are fit for

your Warehouse!

Do you walk off into your storehouse and feel like it’s a messy and disorganized

nightmare? Are forklifts buzzing, pallets spread on the floor, and workers running to

search where products and inventory are found?

Or, are you looking for a warehouse racking system to maximize the current

warehouse space in your establishment and reduce the suffocation in your high-

density storage areas?

You have the ease to reduce clutter, maximize your warehouse space, and increase

worker productivity by funding a warehouse pallet racking plan.

Pallet racking solution can solve several warehouse storage issues, including:

• Getting pallets managed of the floor

• Optimizing your existing warehouse area

• Facilitating the loading and picking of pallets or cartons

• Enhancing worker efficiency with automation required to store and retrieve pallets

At Master Racks Limited , we understand how frustrating it can be to feel like your warehouse

or distribution hub isn’t as organized or working as efficiently as it could be. So we

offer a variety of warehouse solutions to solve any obstacle you may encounter. We

work with our clients to deliver a custom solution that fits their budget and time

frame. We offer everything from a simple particular rack and drive-in pallet racking

to more innovative and complex warehouse technologies and solutions.

This article will discuss warehouse Pallet Rack Layouts, Elements, and Construction

and how they are fit for your warehouse.

Protective plates can be integrated into a racking system to protect impact areas

from forklift or truck damage.

Below are some of the features and design factors for any warehouse storage or

pallet racking system:

Construction

Let’s find out what material is the beams, uprights, and supports made from?

• Roll-formed steel – Our steel coils or sheets are processed through a machine that

rolls the material into the final structural shape. But it is less expensive than

structural steel; however, it is more susceptible to damage from forklifts or trucks.

Once it hurts, the entire structural integrity is gone.

• Steel Structured – Our steels are international standards made from raw iron that is

processed and constructed into its final shape to make it more sustainable and offer

less maintenance throughout its lifecycle. But most of all it is more expensive to

design a pallet rack system using structural steel.

• Hybrid is a mix of structural steel for “impacts” areas such as the rack system’s base,

face, or frames and roll-formed material for the system’s back end or interior parts.

Decking

How will the pallets be stabled? Standard materials are steel beams, wire mesh

decking, carts, gravity rollers, or solid decking.

Post Protectors

Extra protection can be anchored into the ground and planned to take the brunt of a

strike from a forklift or truck. Also, refer as drive-in-rack

Materials Finishing.

We Galvanize the materials used for outdoor applications and epoxy or powder coat

finish to protect against pollution.